[SHORTCODE_ELEMENTOR id=”11524″]

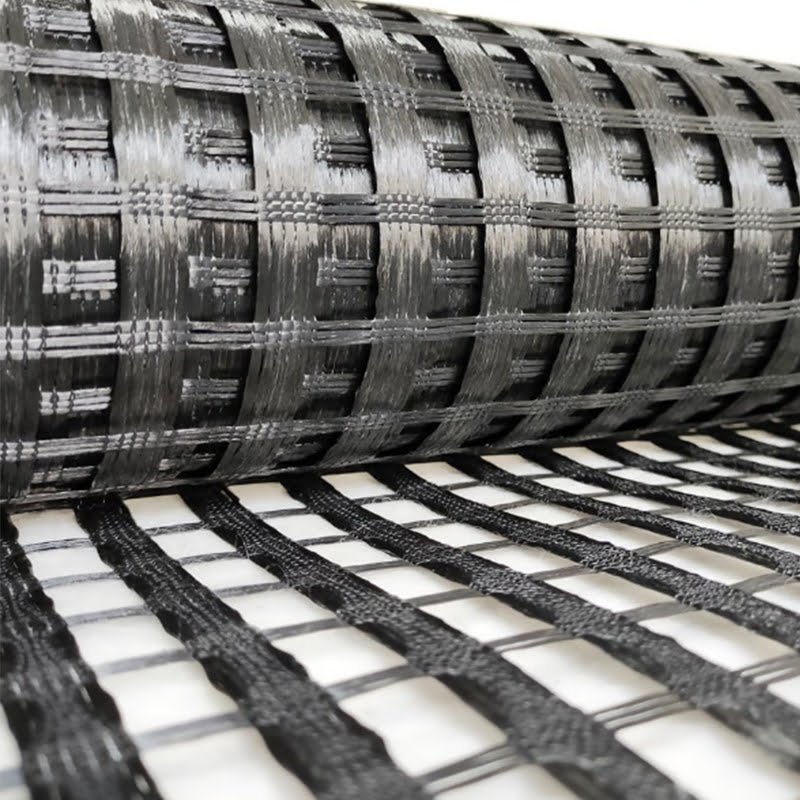

Biaxial Steel Plastic Geogrid

The steel-plastic geogrid is made of high-strength steel wire, specially treated, and polyethylene (PE), and other additives are added to make it a composite high-strength tensile strip through extrusion, and the surface has rough embossing, which is high. Reinforced belt. From this, the single belt is woven or sandwiched at a certain distance vertically and horizontally and is formed by welding its junction points with a special strengthening bonding fusion welding technology, which is a steel plastic geogrid. Steel plastic geogrids are mainly used in highways, railways, ports, etc.