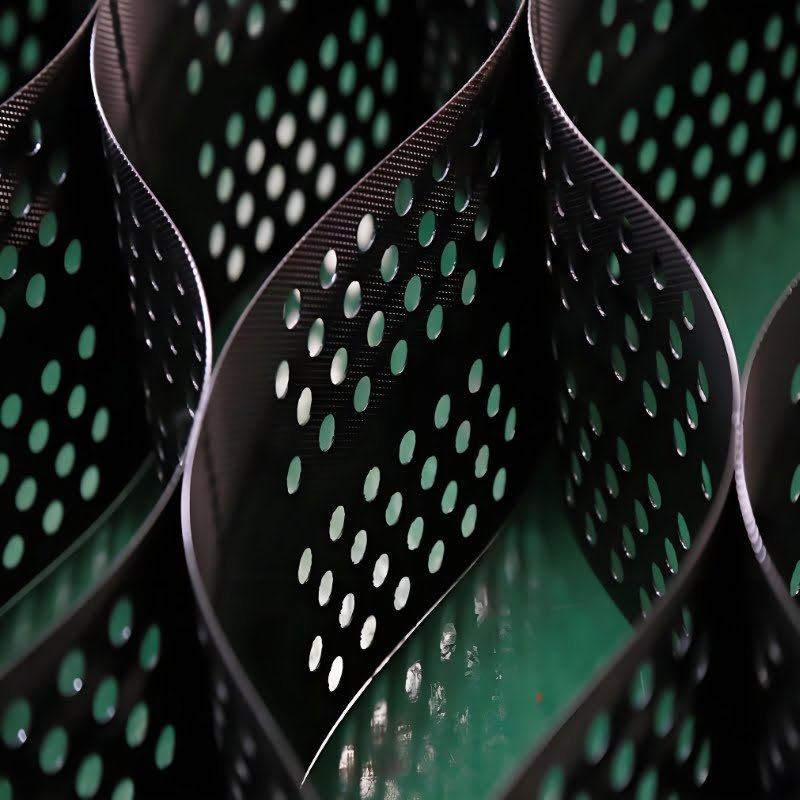

Geomembrane Liner for Pond/ Dam / Landfill / Mining

Welcome to YiShiTong-Leading Geomembrane Manufacturer in China, Our mission is to help our customers build better,

more efficient, more durable, and safer infrastructure projects.

Geomembrane Liner

Thickness: 0.3-3 mm (12-120 mils)

Width: 8m Max (Each geomembrane roll is 8m wide)

Raw Material: PVC/HDPE/LLDPE/EDPM

Standard: GRI GM13/ASTM D638/D4833/D6392/D5321

Delivery: 5-10 days for production

Packing: 50-100m Length/Roll, accept customized

MOQ: Trial Order is acceptable, free sample

Our Geomembrane liners usually used in landfill,pond,water management,and mining project.

Geomembrane Liners

Our Factory

Company Profile

- 20 Years+ Production Experience

- Exports to More than 20 Countries

- 20+ Production Lines

- Total Assets of more than 120 million

- Strict Quality Testing

- ASTM and GRI Standard

- Perfect Technical Support

- High quality and the most cost-effective product

- Serve every customer well

- 100% customer satisfaction guaranteed

Certification

100% Quality Assurance

Product Advantage

Environmentally friendly materials

We use imported HDPE Particles. UV Resistance, Light Weight, and Good Ductility.

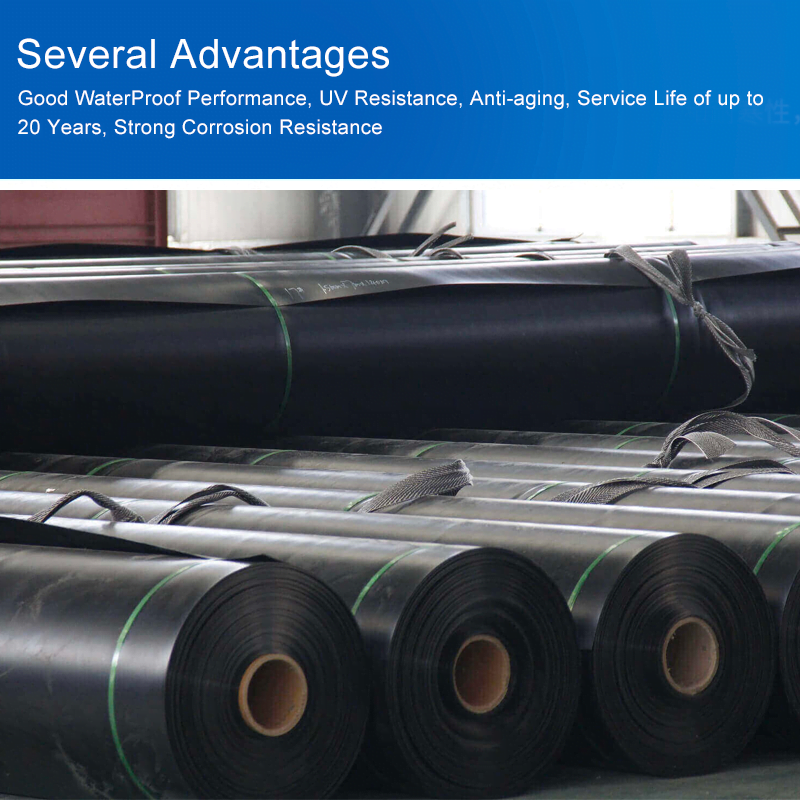

Several Advantages

Good Water-Proof Performance,Anti-aging, Service Life of Up to 20 Years, Strong Corrosion Resistance.

Technical Specification

Click Here Download: Technical Specification.PDF (English Version)

Click Here Download: Techinical Specification.PDF (Spanish Version)

Tell our sales manger your specific project need, we will recommend the best thickness and size for you.

| CJ/T 234-2006 Standard (equivalent to US GRI-GM13 standard) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |||||||

| Density(g/cm³) | ≥0.939 | |||||||||||||

| Tensile yield strength N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 | |||||||

| Tensile fracture strength N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 | |||||||

| Yield Elongation % | ≥12 | |||||||||||||

| Elongation at break % | ≥700 | |||||||||||||

| Right angle tear load N | ≥93 | ≥125 | ≥156 | ≥187 | ≥249 | ≥311 | ≥374 | |||||||

| Puncture resistance strength N | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 | |||||||

| Resistance to environmental stress cracking | ≥300 | |||||||||||||

| Carbon black content(%) | 2.0-3.0 | |||||||||||||

| Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | |||||||||||||

| Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | |||||||||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||||||||

| 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | |||||||||||||

| UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | |||||||||||||

| GB/T17643-2011 Standard | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | 0.3 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |||||||||

| Density(g/cm³) | ≥0.940 | |||||||||||||||||

| Tensile yield strength N/mm | ≥4 | ≥7 | ≥10 | ≥15 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 | |||||||||

| Tensile fracture strength N/mm | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 | |||||||||

| Yield Elongation % | ≥11 | |||||||||||||||||

| Elongation at break % | ≥600 | |||||||||||||||||

| Right angle tear load N | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 | |||||||||

| Puncture resistance strength N | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 | |||||||||

| Carbon black content(%) | 2.0-3.0 | |||||||||||||||||

| Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | |||||||||||||||||

| Atmospheric pressure oxidation induction time (OIT) (min) | ≥60 | |||||||||||||||||

| Low temperature impact embrittlement performance | Pass | |||||||||||||||||

| Dimensional stability(%) | ±2.0 | |||||||||||||||||

Latest Project

School geomembrane barrier

Feasibility Assessments: Conducting comprehensive studies to evaluate

the viability of hydropower projects based on water resources, terrain,

Landfill Industry

Feasibility Assessments: Conducting comprehensive studies to evaluate

the viability of hydropower projects based on water resources, terrain,

Mining industry

Feasibility Assessments: Conducting comprehensive studies to evaluate

the viability of hydropower projects based on water resources, terrain,

FAQ

We are based in Shandong, China, start from 2010,sell to Domestic Market(30.00%),Southeast Asia(20.00%),Africa(20.00%),South America(10.00%),Mid East (10.00%),North America(5.00%),Eastern Asia(5.00%). Our brand is called ecobarrier solution. We are committed to providing high quality geosynthetics products to our customers!

Always a pre-production sample before mass production; Always final Inspection before shipment;

Yes, we'd love to send a free sample to you for an evaluation if you need.

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY; Accepted Payment Type: T/T,L/C,D/P D/A,PayPal,Western Union

We are a professional manufacturer that specialized in geomembrane, geotextile, composite geomembrane etc with ISO9001 certificate more than 15 years.