[SHORTCODE_ELEMENTOR id=”10704″]

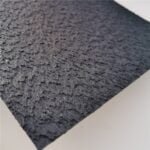

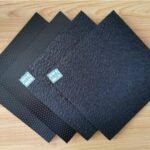

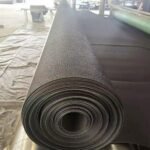

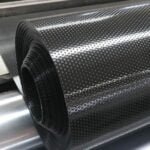

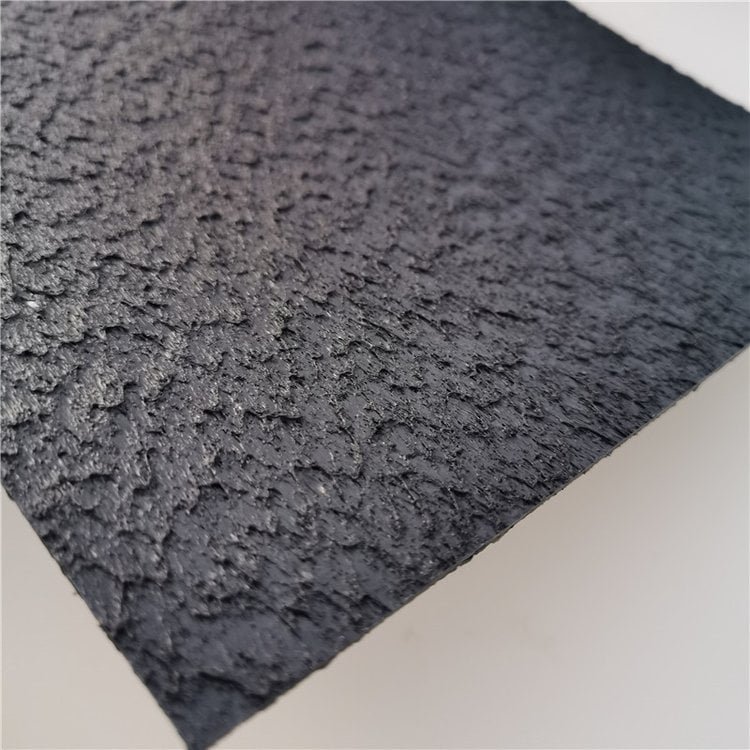

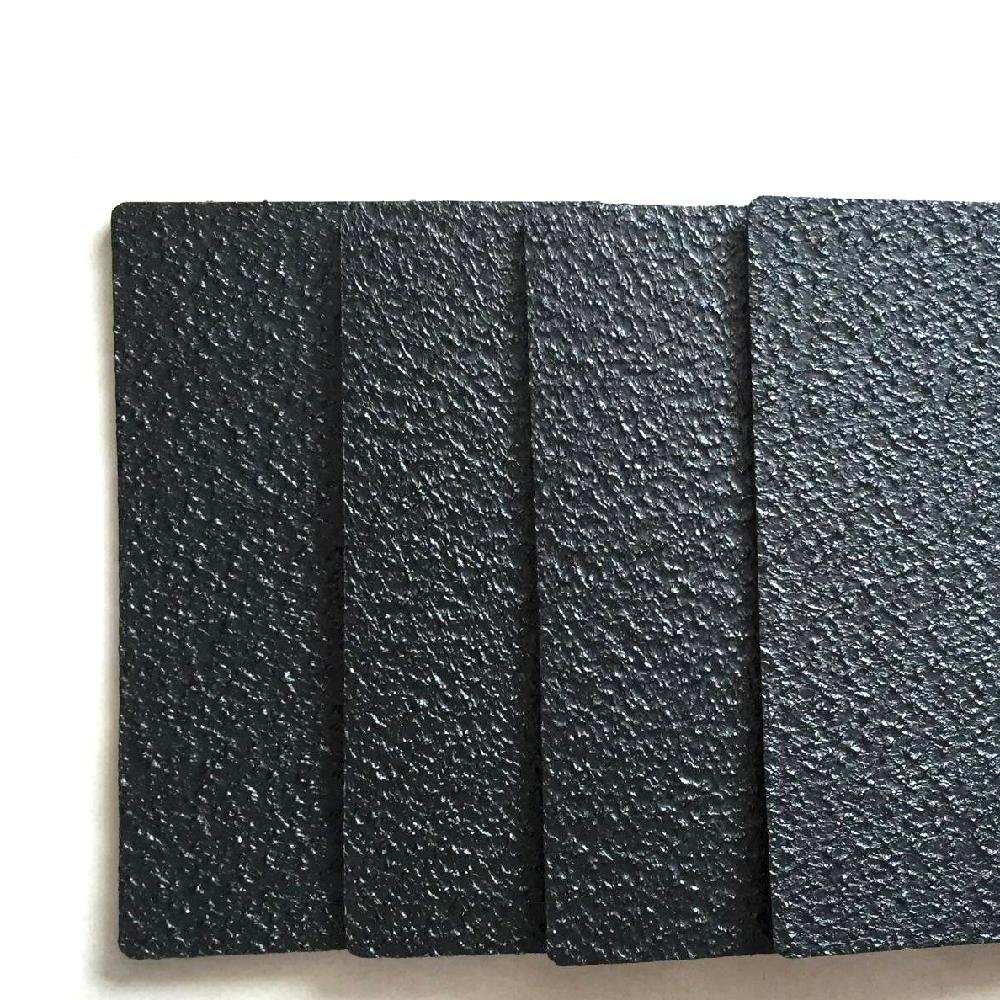

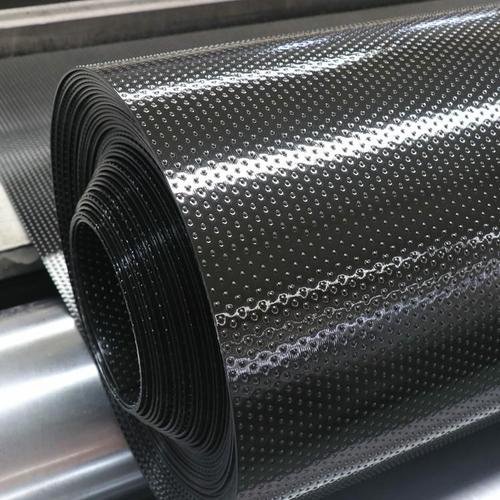

Textured HDPE Geomembrane Liner

HDPE is great because it can handle different temperatures, join together well, resist weather, erosion, cracking, and punctures. It’s especially good for building things underground, like mines, landfills, or sewage systems, because it doesn’t leak. Textured HDPE geomembrane is an improved leak-proof material with one or both sides textured to grip better, making it perfect for slopes and vertical areas to keep them stable and prevent leaks.