[SHORTCODE_ELEMENTOR id=”10727″]

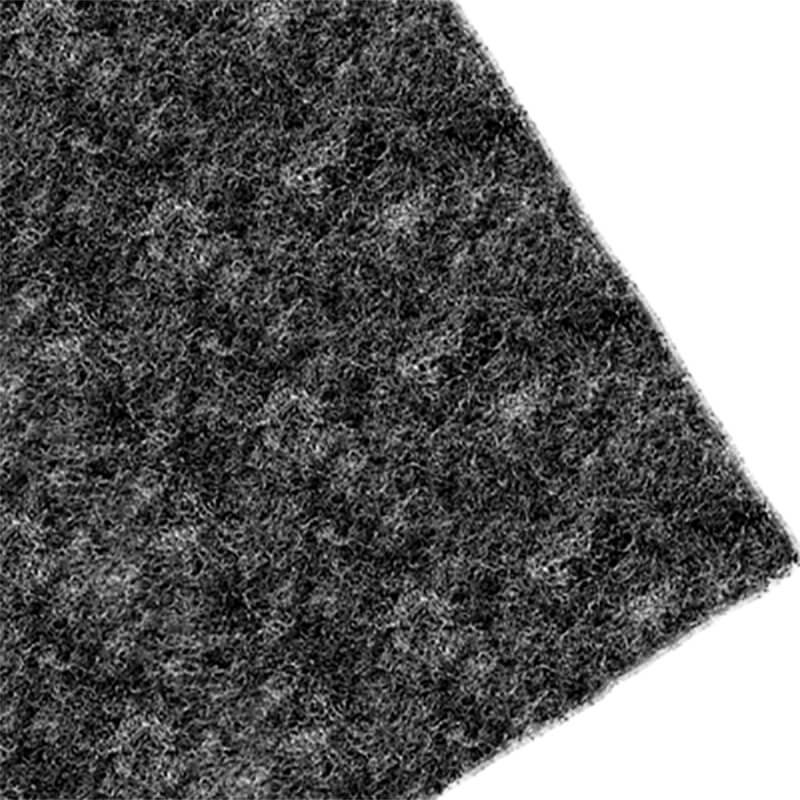

No-Woven Geotextile

Non-woven geotextiles are manufactured by entangling fibers, both long and short, together through either needle punching or other suitable methods. In some instances, thermal treatment is used to improve further the tensile of the geotextile. Because of this manufacturing process, alongside their permeability, non-woven geotextiles are typically used in drainage applications, separation, filtration as well as protection.