[SHORTCODE_ELEMENTOR id=”10714″]

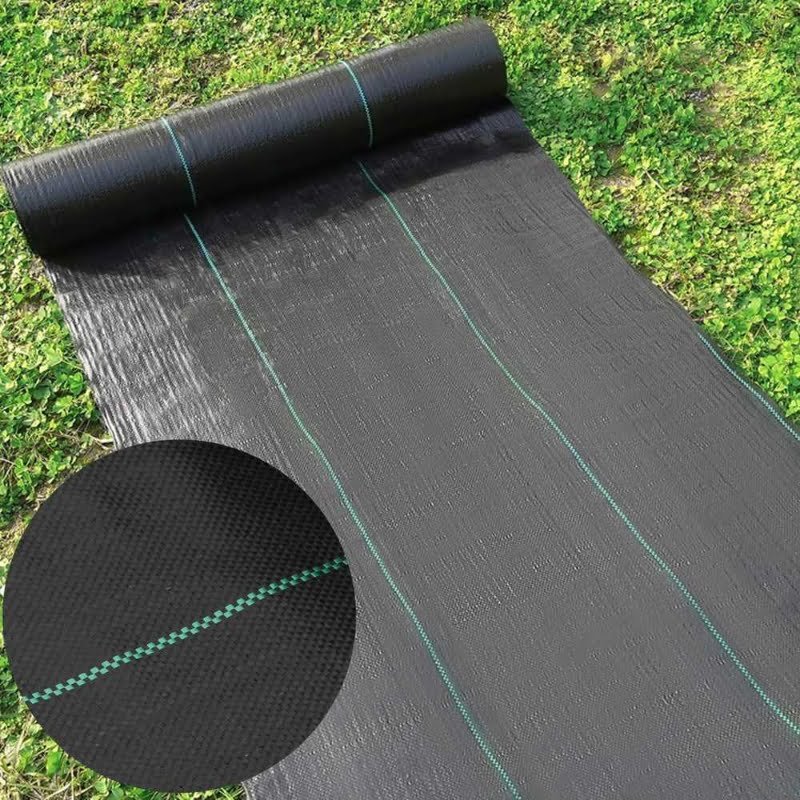

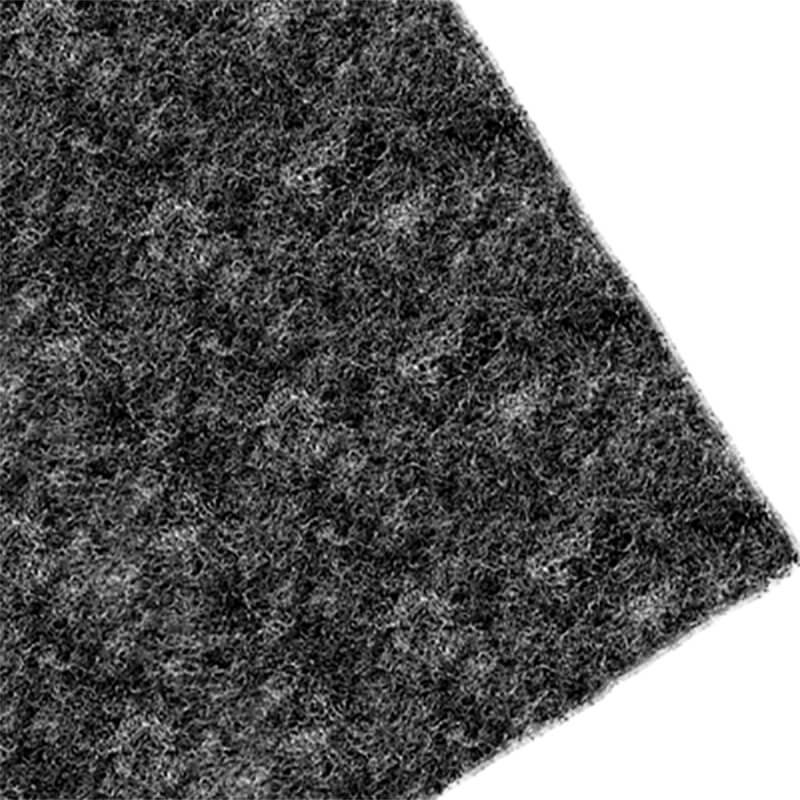

Woven Geotextile

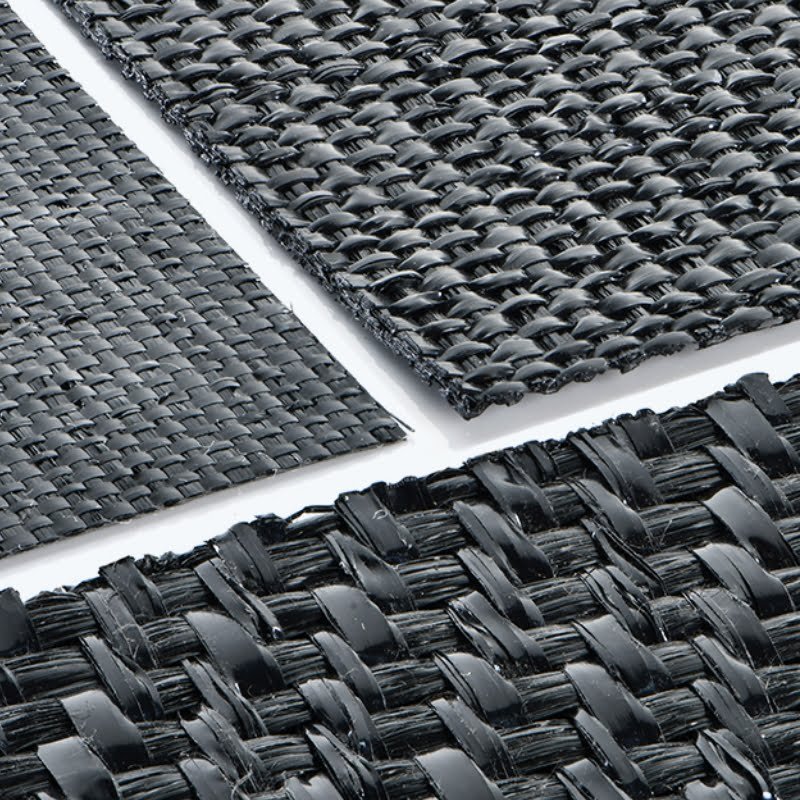

Geotextiles are permeable fabrics that, when used in association with soil, can separate, reinforce, protect, or drain. Typically made from polypropylene or polyester, geotextile fabrics come in three basic forms: woven (resembling mail bag sacking), needle punched (resembling felt), or heat bonded (resembling ironed felt).A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making it less suitable for filtering anything other than clean single-sized soils/fills.