Geotextile is also called geotextile cloth/filter fabric/mat. Those who are unfamiliar with geotextiles will have many questions.

- What is geotextile?

- What are the common types of geotextile?

- The raw material of geotextile

- The common use of geotextile

- What’s the difference between No woven and Woven Geotextile?

- What’s the difference between Geomembrane and Geotextile?

- How to choose the right geotextile for the project?

What is geotextile?

Geotextile, also known as geotextile fabric/mat, is a permeable geosynthetic material made of synthetic fibers through needle punching or weaving. Geotextile is one of the new materials and geosynthetics. The finished product is cloth-like, with a general width of 4-6 meters (the specific width can be customized) and a length of 50-100 meters. Geotextiles are divided into woven geotextiles and non-woven filament geotextiles.

What are the common types of geotextile?

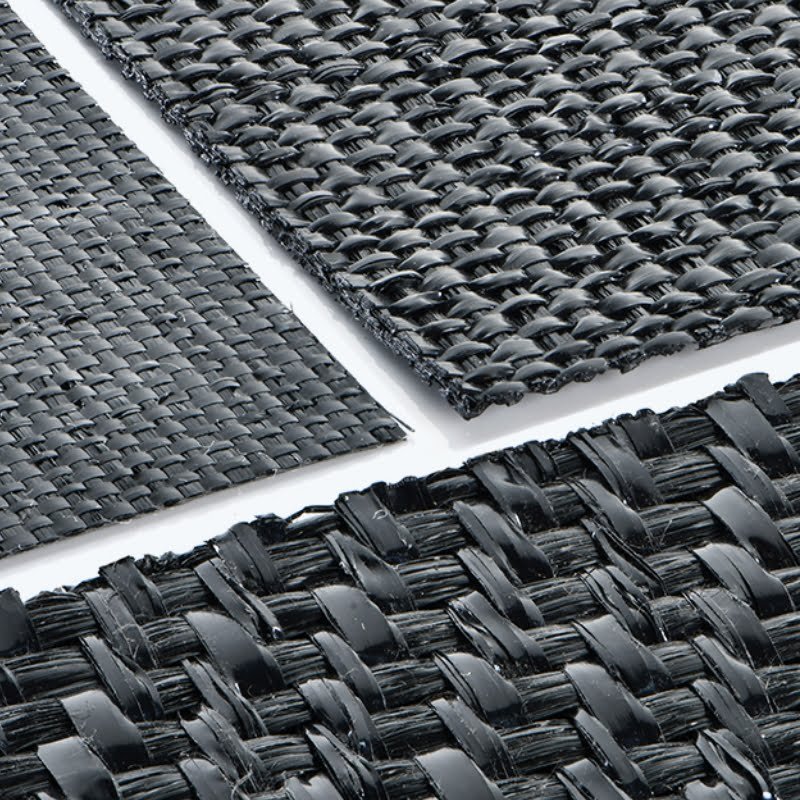

Woven Geotextile

The woven geotextiles are made of interlocking fabric strips that provide strength and stability for the project where geotextiles are needed.

Woven geotextiles are made of polypropylene strips that can withstand a large amount of tension.

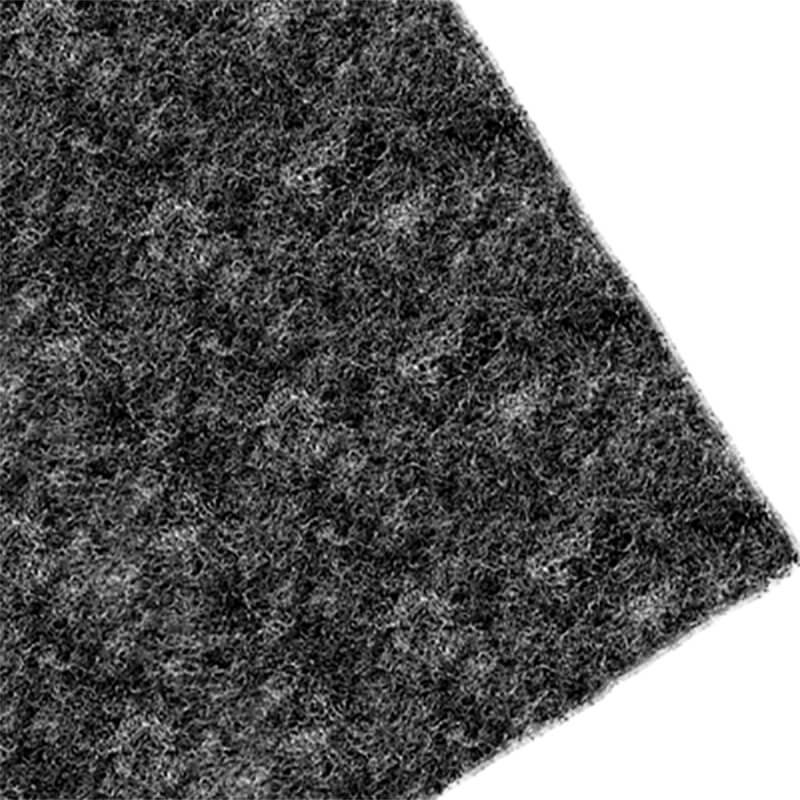

No Woven Geotextile

The non-woven geotextiles are made from either continuous filament yarn or short-staple fibres. The fibres are usually bonded using thermal, chemical, or mechanical techniques or by combining two or all of the methods.

The geo-fibers obtained from mechanical or thermal techniques usually have a thickness of 0.5 to 1mm, while chemically bonded non-woven geotextiles are thicker by up to 3mm.

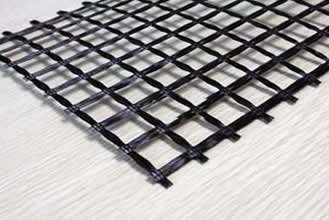

Knitted Geotextile

The knitted geotextiles are made by interlocking a series of loops of yarn together. All the knitted geosynthetics are made using a knitted technique in conjunction with some other geosynthetics manufacturer methods, like weaving.

Common Use of Geotextile

1. Separation

For separation, a geotextile can be installed between two different soil materials.

The geotextile will help to separate dissimilar materials so that the required soil characteristics can be obtained.

2. Filtration

For filtration, geotextiles are used to allow water to move in both directions in a drainage system and can be used to prevent fine aggregates from moving between soil layers.

Geotextiles can be used in both vertical and horizontal applications to help solve drainage problems around the home and along the roads.

3. Reinforcement

When a geotextile is introduced in the soil for soil improvement, its design is based on factors such as:

- Friction or movement restraint

- Support of loads

- Changes in bearing failure plane

Geotextiles are also used on dams and roads being built over poorly graded soils to allow for the steeper embankment.

4. Sealing

A geotextile fabric can be filled with asphalt or other mixes to make it impermeable, thereby making it capable of stopping the flow of water in both directions.

Geotextiles can be used to prevent contamination of soil or groundwater from pollutants above.

5. Protection

For protection, geotextiles can be used to absorb stress and thus reduce or prevent damage and erosion in geotechnical structures.

Embedding geotextiles in construction can help prevent significant damage, like soil erosion and wind damage.

6. Anti-Puncture

Combined with the geomembrane to form a composite waterproof and impermeable material, it plays a role in preventing puncture.

The raw material of geotextile

| Raw Material | Application | Advantages | Disadvantages |

| Polyester | Erosion control, soil stabilization, drainage, filtration | High tensile strength, durability, chemical resistance, UV resistance | Low biodegradability, can be expensive |

| Polypropylene | Separation, filtration, drainage, reinforcement | Lightweight, chemical resistance, high permeability, cost-effective | Lower tensile strength than polyester, susceptible to UV degradation |

| Polyethylene | Moisture barrier, separation, lining | Impermeable, chemical resistance, flexibility, cost-effective | Low tensile strength, susceptible to UV degradation |

| Polyamide (Nylon) | Reinforcement, high-strength applications | High tensile strength, abrasion resistance, durability | Expensive, low UV resistance |

| Natural fibers (jute, coir) | Erosion control, bioengineering | Biodegradable, environmentally friendly | Low durability, susceptible to degradation |

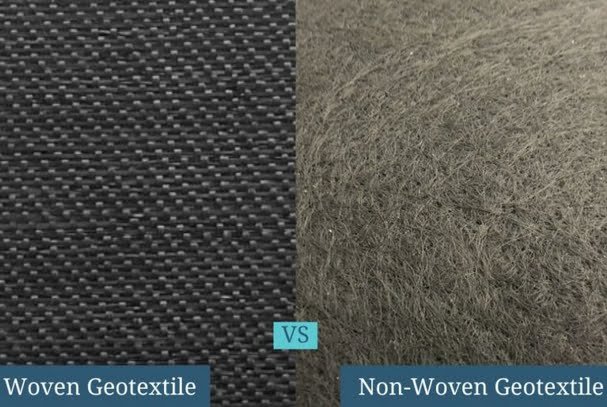

What’s the difference between No woven and Woven Geotextile?

Non-woven geotextiles and woven geotextiles are both types of geotextiles. Their differences mainly lie in their different materials and production processes.

1. Material Comparison

Non-woven geotextiles are typically manufactured from synthetic fibers such as polyester, polypropylene, or nylon. These materials undergo a series of integrated processes including melt extrusion, fiber formation (e.g., spunbonding or meltblown), and subsequent bonding (e.g., thermal or mechanical) to create a non-woven fabric structure. Woven geotextiles, conversely, are fabricated by interlacing yarns derived from synthetic fibers or polymers, primarily polyester and polypropylene, into a woven textile configuration.

2. Production Process

Non-woven geotextiles are manufactured primarily through two distinct processes:

- Thermal Bonding: This process utilizes heated air to induce the melting and subsequent bonding of synthetic fibers, resulting in a cohesive non-woven fabric structure. This method is often employed in the production of spunbond or meltblown non-wovens.

- Needle Punching: In this process, barbed needles mechanically interlock the fibers within a fibrous web, enhancing the strength and stability of the non-woven material. Needle punching is commonly used to create needle-punched non-woven geotextiles.

In contrast, woven geotextiles are fabricated through traditional weaving techniques, where yarns are interlaced perpendicularly to form a stable and robust textile structure.

3. Pros and Cons of NO-Woven Geotextile

Advantages:

- Lightweight and Flexible: Easier handling, transporting, and installing than woven geotextiles.

- High Permeability allows for efficient water flow through the fabric, making it suitable for drainage and filtration applications.

- Cost-Effective: Typically less expensive to manufacture than woven geotextiles.

- Good Elongation: Offers better resistance to deformation under stress than woven geotextile.

Disadvantages:

- Lower Tensile Strength: Generally less resistant to tearing and puncture than woven geotextiles.

- Less Durable: More susceptible to UV exposure and mechanical damage degradation, leading to a shorter lifespan.

- Quality Variability: Manufacturing processes can result in inconsistencies in product quality.

4. Pros and Cons of Woven Geotextile

Advantages:

- High Tensile Strength: Offers superior resistance to tearing, puncture, and abrasion compared to non-woven geotextiles.

- Durable: More resistant to degradation from UV exposure and mechanical damage, resulting in a longer lifespan.

- Stable Properties: Consistent quality due to standardized manufacturing processes.

Disadvantages:

- Lower Permeability: The fabric’s less efficient flow of water through it makes it less suitable for certain drainage applications.

- Less Flexible: More difficult to handle, transport, and install than non-woven geotextiles.

- Higher Cost: Typically more expensive to manufacture than non-woven geotextile.

The choice between non-woven and woven geotextile depends on the specific application and project requirements. Non-woven geotextiles are often preferred for applications where flexibility, permeability, and cost-effectiveness are priorities, while woven geotextiles are chosen for projects that demand high strength, durability, and dimensional stability.

What’s the difference between Geomembrane and Geotextile?

Geomembranes and geotextiles are both types of geosynthetics used in various civil engineering and construction applications, but they serve different purposes due to their distinct properties:

Geomembrane:

- Material: Typically made of continuous polymeric sheets (e.g., HDPE, PVC, or other synthetic materials).

- Impermeability: Designed to be impermeable, acting as a barrier to prevent the flow of liquids or gases.

- Applications: It is primarily used for containment and lining systems in landfills, ponds, canals, reservoirs, and other structures where preventing leaks and seepage is crucial.

Geotextile:

- Material: Made of permeable woven or non-woven fabrics from synthetic or natural fibers.

- Permeability: Allows to flow liquids and gases through the fabric while filtering out soil particles.

- Applications: Used for separation, filtration, drainage, reinforcement, and erosion control in various civil engineering projects like roads, embankments, retaining walls, and landfill covers.

| Feature | Geomembrane | Geotextile |

| Permeability | Impermeable | Permeable |

| Primary Function | Containment and Barrier | Separation, Filtration, Drainage, Reinforcement |

| Material | Continuous polymeric sheets | Woven or Non-woven fabrics |

| Typical Uses | Liners, covers, containment systems | Roads, embankments, drainage systems, filters |

In some applications, geomembranes and geotextiles are used together. For instance, in a landfill, a geomembrane may be the primary barrier layer to prevent leachate migration, while a geotextile layer on top provides protection, filtration, and drainage.

How to choose the right type of geotextile

Tailoring geotextile fabric to your project’s specific needs is crucial for its success. To achieve this, clearly define your project requirements:

1. What are the primary functions of the geotextile in your project?

- Is it primarily for separation, filtration, drainage, reinforcement, or erosion control? Each function requires different properties from the geotextile.

2. What are your project site’s specific soil conditions and environmental factors?

- What is the soil type (particle size distribution, permeability)?

- Will the geotextile be exposed to harsh chemicals, extreme temperatures, or high levels of UV radiation?

3. What are the anticipated loads and stresses the geotextile will endure?

- Will it be subjected to heavy traffic, static loads, or dynamic forces?

By carefully evaluating these factors, you can determine the necessary properties of the geotextile, such as:

- Strength: Tensile, tear, and puncture resistance.

- Permeability: The rate at which water flows through the fabric.

- Opening Size (AOS): The size of soil particles the fabric can filter.

- Durability: Resistance to UV radiation, chemicals, abrasion, and biological degradation.

Answering these questions will ensure you choose the right geotextile.