[SHORTCODE_ELEMENTOR id=”11511″]

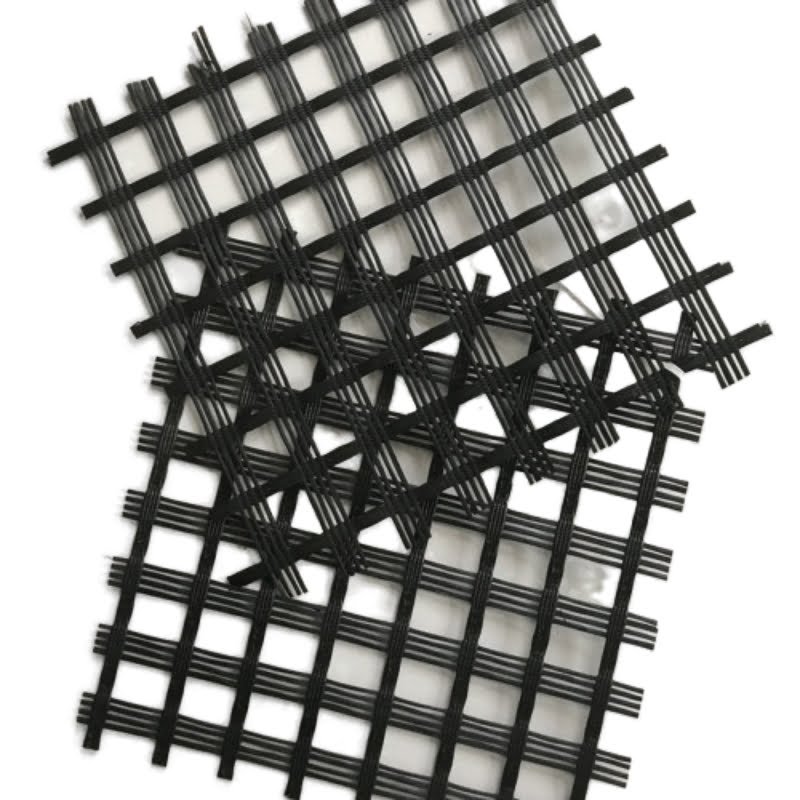

Fiberglass Geogrid

The warp-knitted glass fiber geogrid is made of glass fiber by weaving and coating. It has high longitudinal and lateral tensile strength, low elongation, and high tensile modulus.

Warp-knitted fibreglass geogrids can be used in engineering fields such as road and airport pavement, water conservancy dam surface layer reinforcement, and more.