What is LLDPE Geomembrane ?

Applications

-

Irrigation ponds, canals, ditches & water reservoirs

-

Gravel Driveway, drainage, road construction.

-

Landfill cells, covers, & caps

Testing Standard

-

GRI GM 6/9/11/13/14/19

-

ASTM D792/D1004/D1238/D1505/D1603/D3895

-

ASTM D4218/D4833/D5199/D5397/D5596

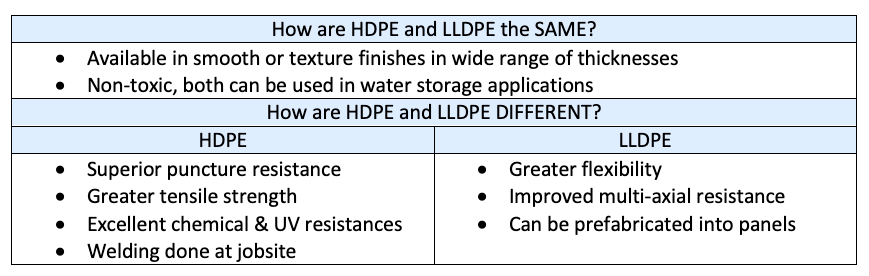

Difference between HDPE and LLDPE

Technical Specification

Thickness: 0.3-3 mm ( 12-120 mils), Material: High-quality HDPE. Price from $0.5 SQM

| CJ/T 234-2006 Standard (equivalent to US GRI-GM13 standard) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |||||||

| Density(g/cm³) | ≥0.939 | |||||||||||||

| Tensile yield strength N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 | |||||||

| Tensile fracture strength N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 | |||||||

| Yield Elongation % | ≥12 | |||||||||||||

| Elongation at break % | ≥700 | |||||||||||||

| Right angle tear load N | ≥93 | ≥125 | ≥156 | ≥187 | ≥249 | ≥311 | ≥374 | |||||||

| Puncture resistance strength N | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 | |||||||

| Resistance to environmental stress cracking | ≥300 | |||||||||||||

| Carbon black content(%) | 2.0-3.0 | |||||||||||||

| Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | |||||||||||||

| Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | |||||||||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||||||||

| 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | |||||||||||||

| UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | |||||||||||||

| GB/T17643-2011 Standard | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | 0.3 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |||||||||

| Density(g/cm³) | ≥0.940 | |||||||||||||||||

| Tensile yield strength N/mm | ≥4 | ≥7 | ≥10 | ≥15 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 | |||||||||

| Tensile fracture strength N/mm | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 | |||||||||

| Yield Elongation % | ≥11 | |||||||||||||||||

| Elongation at break % | ≥600 | |||||||||||||||||

| Right angle tear load N | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 | |||||||||

| Puncture resistance strength N | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 | |||||||||

| Carbon black content(%) | 2.0-3.0 | |||||||||||||||||

| Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | |||||||||||||||||

| Atmospheric pressure oxidation induction time (OIT) (min) | ≥60 | |||||||||||||||||

| Low temperature impact embrittlement performance | Pass | |||||||||||||||||

| Dimensional stability(%) | ±2.0 | |||||||||||||||||

Technical Notes

1. LLDPE is a very technical product to work with. It must be installed by certified welding technicians using specialized welding equipment to ensure performance.

2. Installations are temperature and poor weather-sensitive.

3. 40 mil HDPE liner requires extra effort to ensure that the subgrade is in excellent condition. It is suitable as an upgrade from products like the 20 mil RPE for larger installations and is an excellent secondary containment liner on multi-layer systems (for example; subgrade, geotextile layer, 40 mil

4. HDPE layer, drainage net layer, 60 mil HDPE layer, geotextile layer, fill.)

5. 60 mil HDPE liner is the staple of the industry and is suitable for most applications.

6. 80 mil HDPE liner is a thicker design for more aggressive subgrades.

Latest Project

School geomembrane barrier

Feasibility Assessments: Conducting comprehensive studies to evaluate

the viability of hydropower projects based on water resources, terrain,

Landfill Industry

Feasibility Assessments: Conducting comprehensive studies to evaluate

the viability of hydropower projects based on water resources, terrain,

Mining industry

Feasibility Assessments: Conducting comprehensive studies to evaluate

the viability of hydropower projects based on water resources, terrain,

Request Info or Get a Quote

We welcome the opportunity to work with you on your next infrastructure project. Send us a message, and our team will get back to you promptly.